TEMPERATURE SENSOR RESPONSE TIME OPTIMIZATION

Partner - Continental Automotive Czech Republic s.r.o

automotive

Together with the research and development staff of Continental Automotive Czech Republic s.r.o., a tool for speeding up the design of thermal sensors and their optimization was developed.

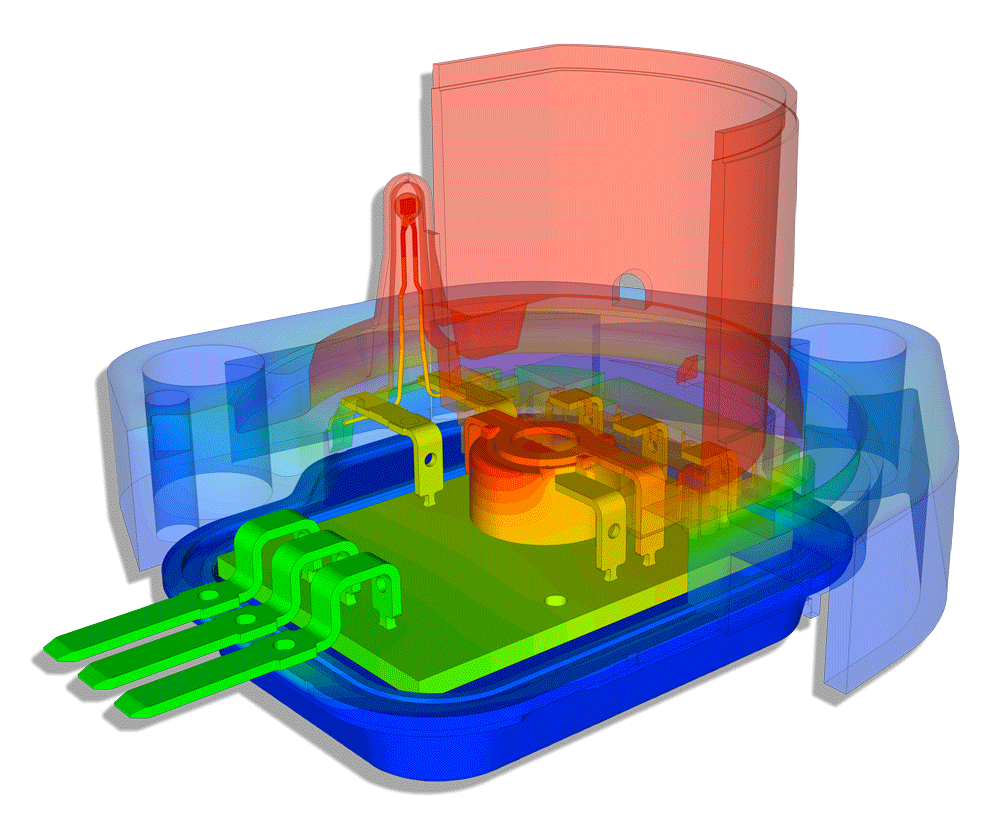

In the thermal sensors design, it is necessary to ensure their fast response to the fullest possible extent of the operational parameters such as changeable ambient temperature given by the climate change or rapid change in temperature of the measured operating fluids.

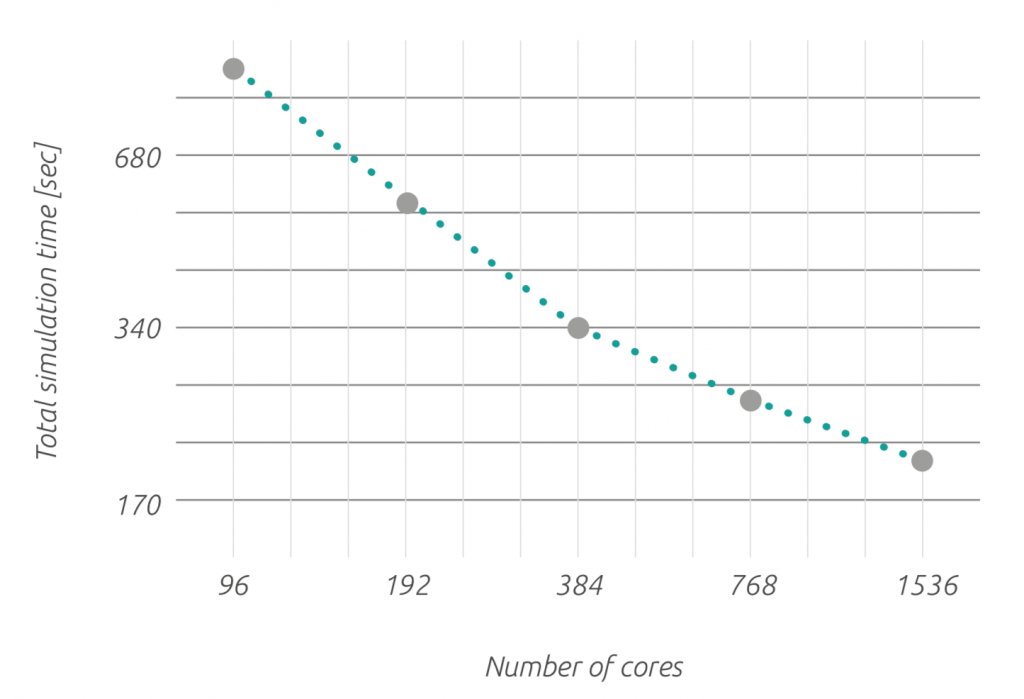

The response of the sensor is affected by both the material properties of its individual components and its geometry itself. In order to set the optimal parameters for the individual components and assess the effect they have on the total response time, an automated tool based on the open source ESPRESO library was created.

In order to compute the response curve required for assessing optimal functionality of the thermal sensor, it is necessary to perform tens or even hundreds of independent, computationally expensive simulations of the response. Using the ESPRESO library based on the finite element method in combination with optimal parallel algorithms, which allow the HPC infrastructure to be used to its full extent, reduces the time required for achieving optimal parameters to its minimum. Moreover, using the open-source solution also minimizes the economic costs incurred when using commercial software solutions and allows the functionality to be extended to other products included in the wide portfolio of Continental Automotive Czech Republic s.r.o.

Partner's note

We highly appreciate our long-term

cooperation with IT4Innovations National

Supercomputing Center. Their consultations

during solving complex problems are led

professionally and helpfully. They are able

to reflect specific impacts of the product,

needs, and opportunities of our company. The

achieved results presented in well-arranged

reports correlate with real tested samples.

The output also includes a computational

model, which can be used for future

optimization. We can therefore consider our

cooperation with IT4Innovations to be highly

productive, and we look forward to our other

joint projects in the future.

Pavel Žáček

Mechanical Engineer Leader BU Sensors & Actuators - Continental Automotive Czech Republic s.r.o